Chenguang Conveyor Belt

The world leader in

flame retardant conveyor belts

Innovative technology · excellent quality · global service

Chenguang Conveyor Belt

The world leader in

flame retardant conveyor belts

Innovative technology · excellent quality · global service

Shandong Chenguang has been deeply engaged in the transportation field for more than 20 years, building a product system, relying on international cooperation and manufacturing accumulation, and has cases in many industries, showing comprehensive strength.

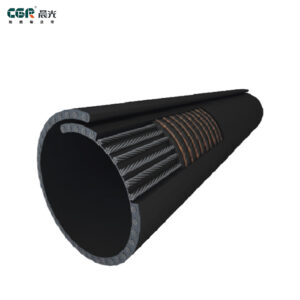

Global Expert in Flame-Retardant Conveyor Solutions

0

Annual production

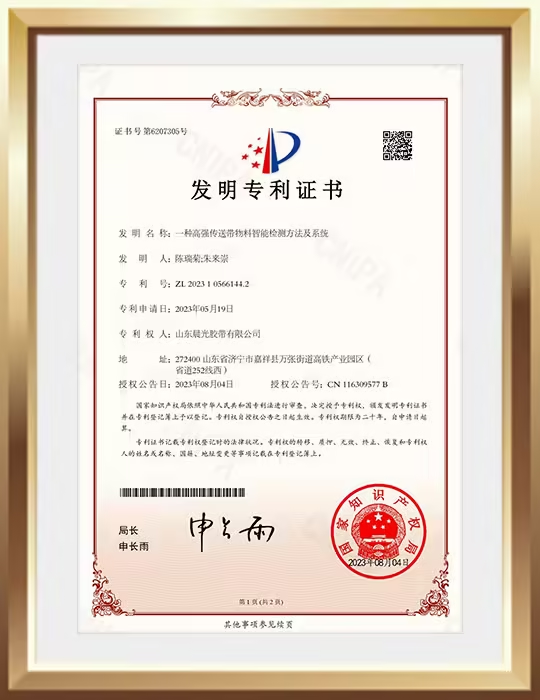

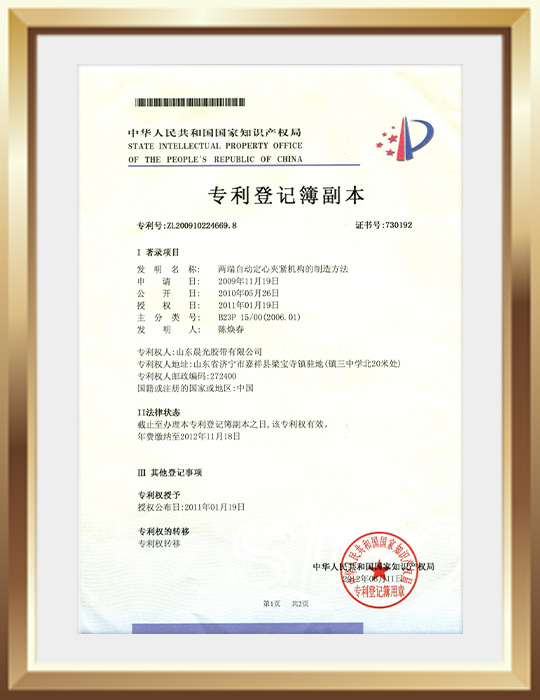

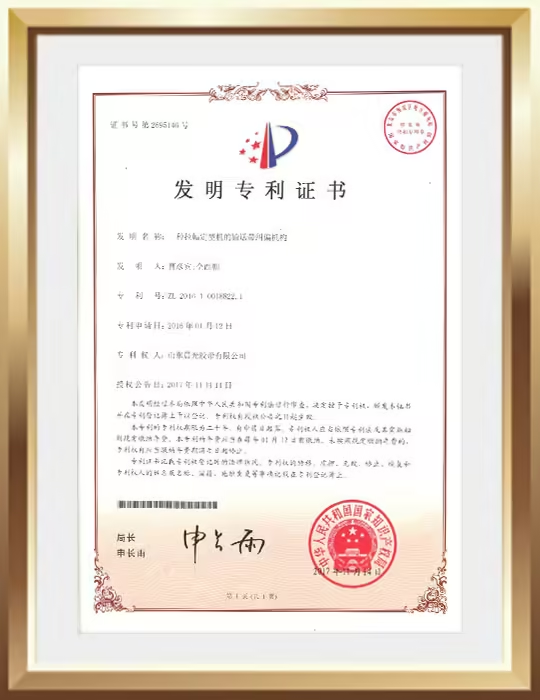

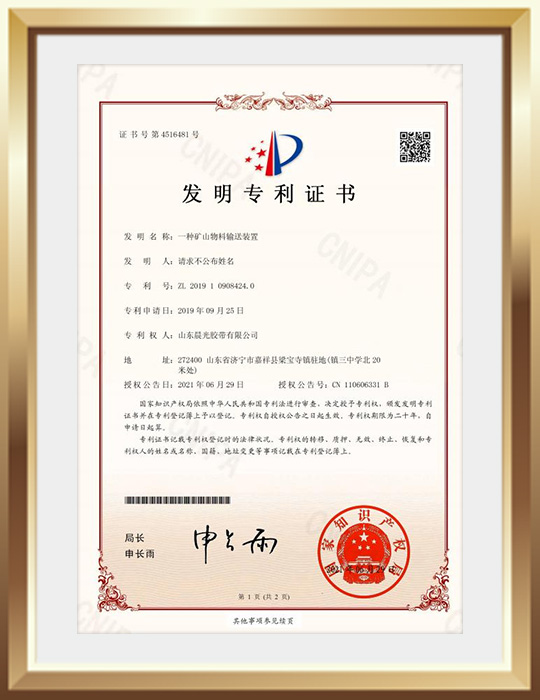

0

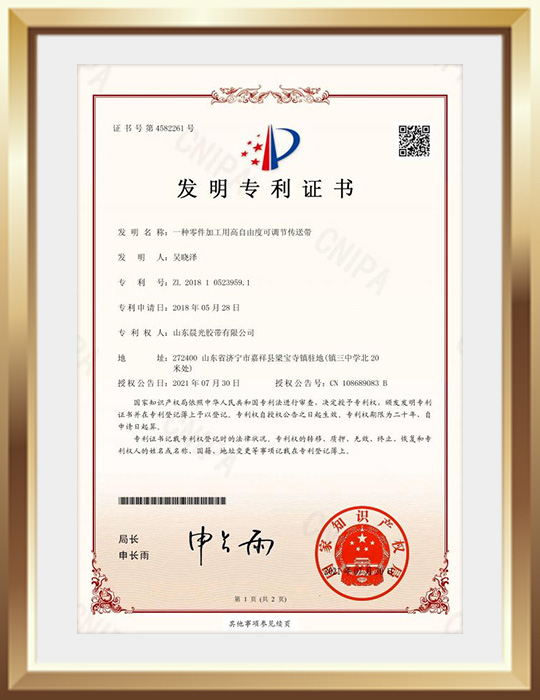

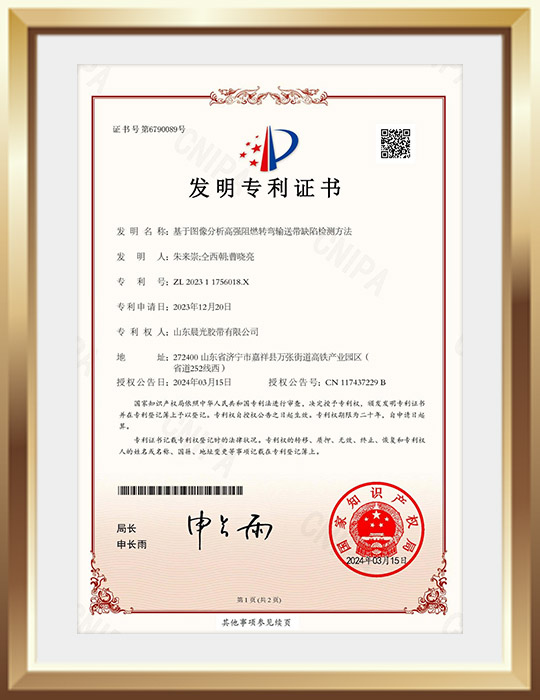

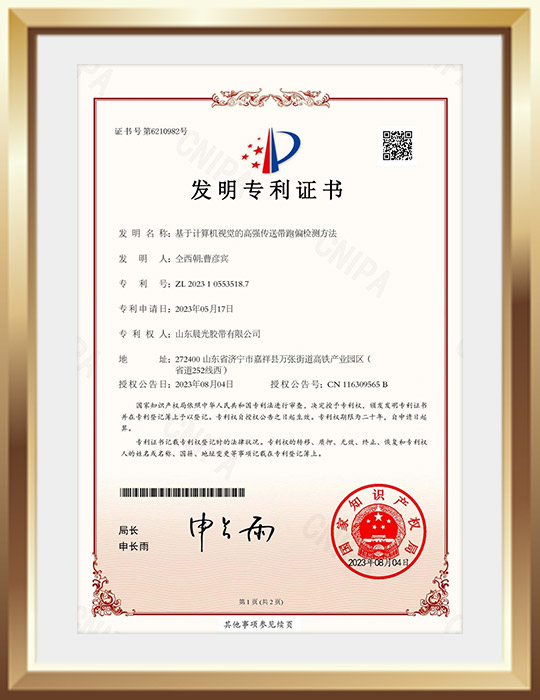

Patent Certificate

0

Top Talents

0

Domestic and foreign sales

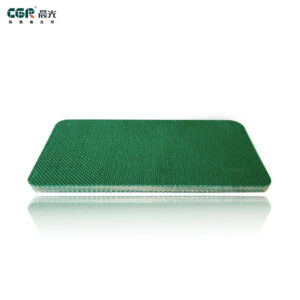

The world leader in flame retardant conveyor belts

Chenguang Conveyor Belt

Shandong Chenguang Conveyor Belt Co., Ltd.is located in Jiaxiang, Jining, Shandong. It has invested tens of billions of yuan and covers an area of more than 270,000 square meters. It specializes in the production of conveyor belts, has strong technical force, and its products are exported to both domestic and abroad.

Enterprise Strength

Corporate Environment

Industry Solutions

Customer Cases

Core Advantages

Why book with us

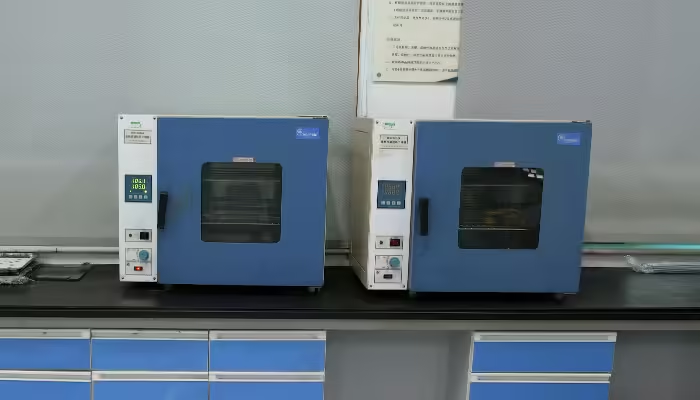

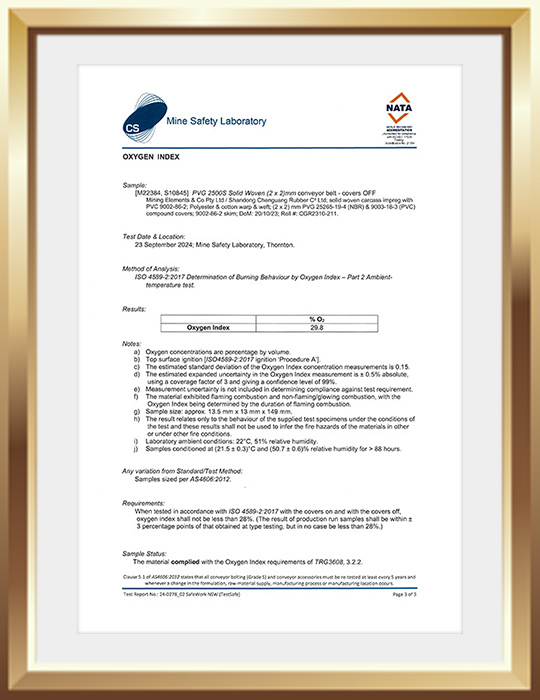

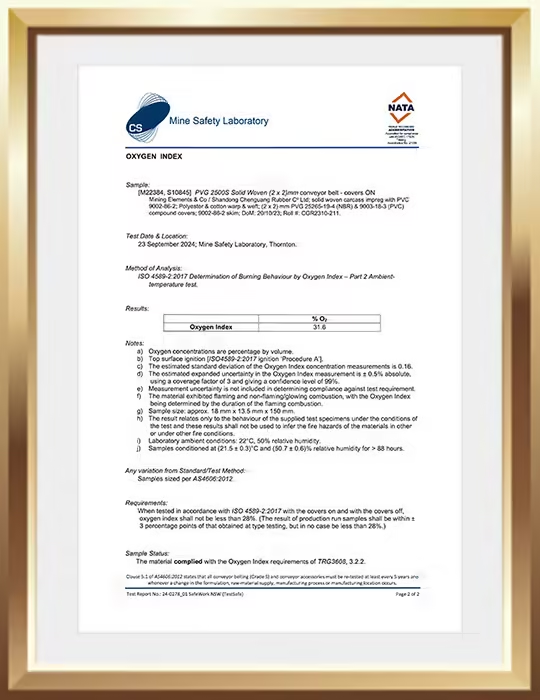

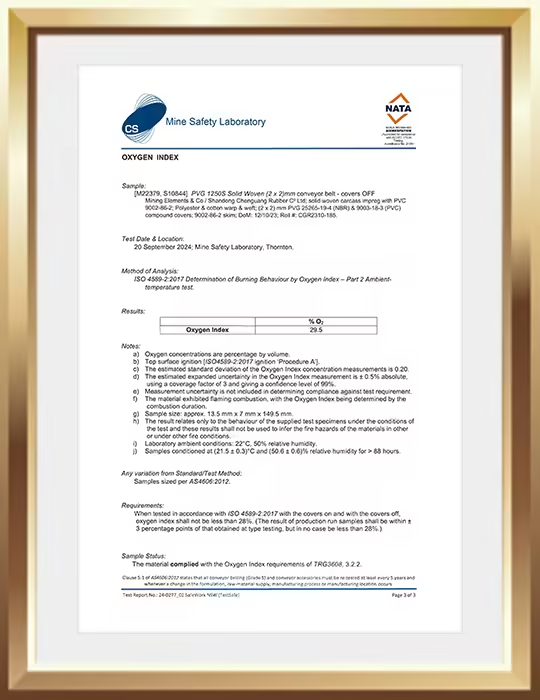

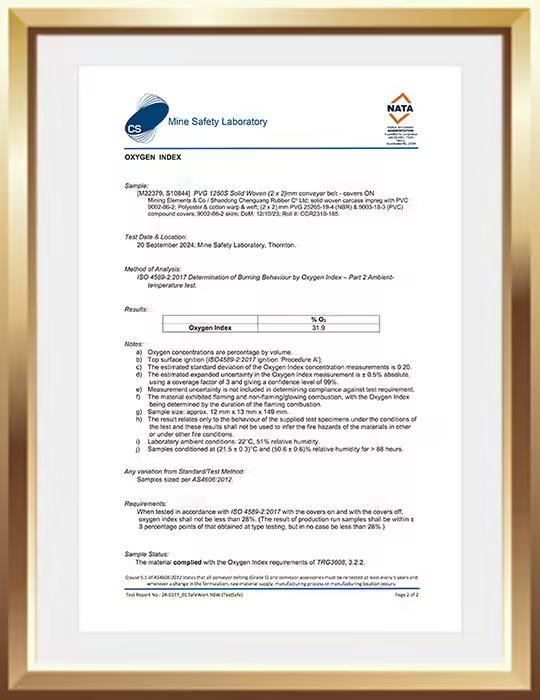

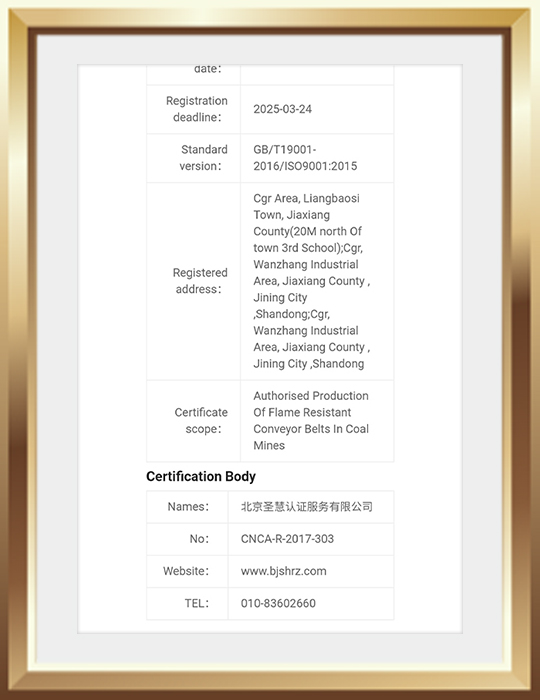

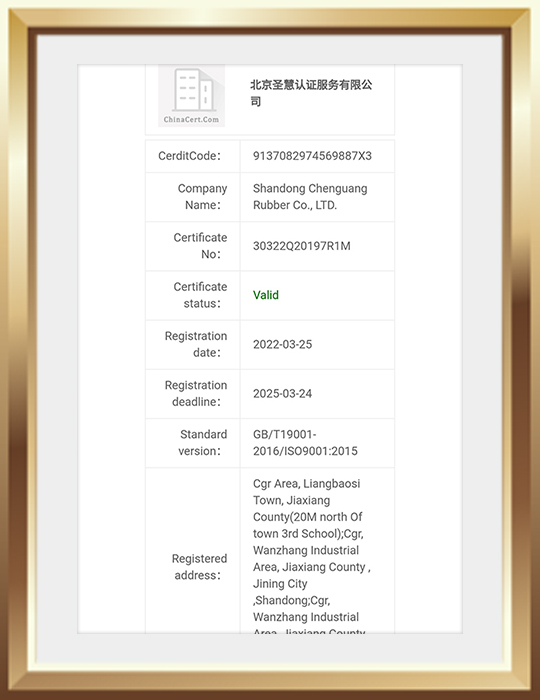

Passed ISO9001/14001/45001 three-system certification, A-level laboratory full quality control, and full quality traceability from raw materials to finished products.

Win-win partner

The best conveyor belt for your business

Chenguang Conveyor Belt Meet your needs

We have professional and innovative R&D engineers

Chenguang Conveyor Belt Technology Center

Meet our R&D engineers who work to develop advanced conveyor belting technology. From material innovation to product optimization, they are committed to ensuring our conveyor belts meet the highest industry standards, bringing greater efficiency and reliability to your operations.

Our Mission

Through innovative research and development, we create conveyor belt solutions with excellent performance, safety, and durability to overcome industry challenges, promote sustainable development, and enable customers to improve efficiency.

Our Vision

As a global leader in the research and development of conveyor belt technology, we set new industry standards through continuous innovation and shape the future of material transportation with intelligent, green and high-performance solutions.

EXPLORE OUR R & D JOURNEY

Dive into the stories of our technological breakthroughs, meet the brilliant minds behind our innovations, and discover how our R & D efforts can elevate your conveyor system performance.

“Our R & D focus is on turning challenges into opportunities. Every patent, every innovation, is a step towards better, safer, and more efficient material conveyance for the world.”

Head of Chenguang Conveyor Belt CenterLeo Chen