Learn more about Chenguang

Generate Devices

Innovative technology · excellent quality · global service

Intelligent production line

Fine control of the entire process

The company has a “high starting point and high standards”. The equipment comes from well-known manufacturers and cooperates with scientific research institutions to develop formulas to ensure advanced equipment technology. Equipped with British Farrell, XM-160 internal mixer and CNC auxiliary machine, the rubber compound is mixed evenly.

XYLJ-1900 extruder and four-roll calender are introduced to produce conveyor belts below 2400mm, which are formed in one step. 13 flat plate vulcanization lines (including XLB-Q2600×12600) meet the needs of products within 2400mm. Oil medium heating, temperature difference ±1℃, high automation, and quality assurance.

The whole core flame retardant conveyor belt has 8 plasticizing lines, high temperature one-time lamination, and full-process intelligent control. The product has strong adhesion, impact resistance, and long service life. The belt core is independently woven according to the MT/T317 standard to ensure quality. The product meets and exceeds multiple standards.

0

Vulcan Line(Eco-heat)

0

Plastic Line(Low-energy)

0

Stable(Green Ops)

0

㎡/Yr(Eco-cap)

Brand History

Brand growth mark

Start-up breaks through the market and enters the industry TOP10 through R&D upgrade. Global layout, annual production capacity of 35 million square meters.

Brand status

Flame retardant leads passers-by

We focus on flame retardant belts, become a global leader with our technology and scale, and protect the industry’s safe transportation.

Brand Features

Innovation + Temperature

The professional team drives innovation, adheres to the dual concepts of “users + employees”, and builds high-quality solutions.

Future Outlook

Towards a new global vision

Continue the “quality + technology” gene, drive upgrades and expand internationally; deepen global cooperation and jointly open a new chapter for the industry.

Brand Development History

The growth path from breaking through to leading

The company opened up the market with quality and service and won the trust of customers. It has deepened its R&D and introduced advanced technologies with expert partners to ensure product safety and efficiency, and has become one of the top 10 conveyor belt companies in the 2022-2023 conveyor belt industry. Today, its products are exported all over the world, with an annual production capacity of 35 million square meters, firmly leading the industry.

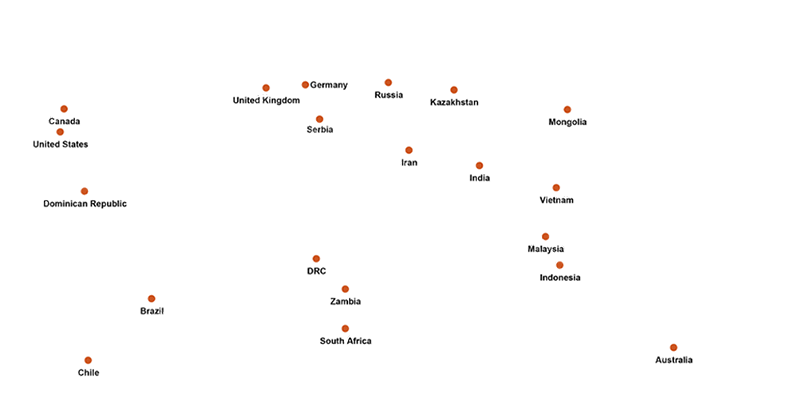

Taking quality as the anchor, expanding the global

Global layout and innovation prospects of M&G Adhesive Tape

Inherit the “quality, technology, and service” genes and accelerate product/process innovation; anchor the international market, deepen global collaboration, and jointly build a new future for the transportation industry.