Learn more about Chenguang

Technology Center

Innovative technology · excellent quality · global service

0

Repurchase rate

0

Patent Certificate

0

Top Talents

0

Results conversion rate

EXPLORE OUR R & D JOURNEY

Dive into the stories of our technological breakthroughs, meet the brilliant minds behind our innovations, and discover how our R & D efforts can elevate your conveyor system performance.

“Our R & D focus is on turning challenges into opportunities. Every patent, every innovation, is a step towards better, safer, and more efficient material conveyance for the world.”

Head of Chenguang Conveyor Belt CenterLeo Chen

CGR Technology Center supports

Chenguang Conveyor Belt Customer Case

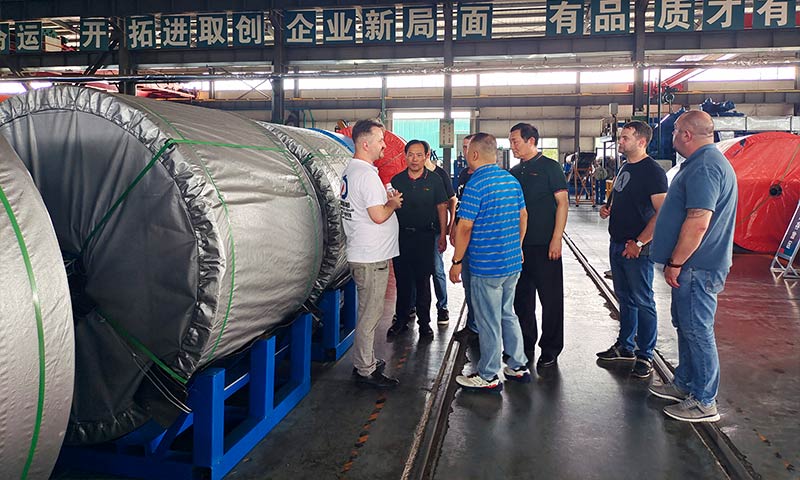

Welcome to Chenguang Belt’s cooperation site with Russian customers. We focus on the long-distance transportation problems in mining underground. We use customized conveyor belt solutions to reshape the efficient transportation pattern and inject reliable momentum from working condition diagnosis to product implementation.

Cooperation Background

The conveyor belts of Russian customers have poor wear resistance and are easy to break, which puts pressure on efficiency and cost. Chenguang technical services provide a breakthrough.

Customer Testimonials

Russian customer: “M&G’s customized solution solves the pain point of ‘working but not working well’, with precise adaptation of details. The conveyor line is ‘stable, economical and long-lasting’, which is very reassuring!”