Actualmente, la mayoría de los materiales a granel transportados mediante cintas transportadoras son transportadores de banda plana. La cinta transportadora plana se coloca sobre el transportador y forma una ranura natural junto al ángulo de la ranura del rodillo lateral del transportador, transportando el material. Esta estructura de transporte es propensa a la proyección y derrame de polvo de material a granel, o al flujo de materiales con disolventes, lo que causa una grave contaminación ambiental y pérdidas de material. La cinta transportadora tubular de caucho es el principal equipo de soporte del transportador de banda tubular. Se basa en los defectos de transporte mencionados anteriormente. La cinta transportadora adopta una forma tubular durante todo el proceso de transporte de materiales. Los materiales se transportan en un sistema cerrado durante todo el proceso, y se logran las características técnicas de giro de radio pequeño y disposición de ángulos de inclinación amplios. Este proyecto también se adapta plenamente a las necesidades actuales de protección ambiental.

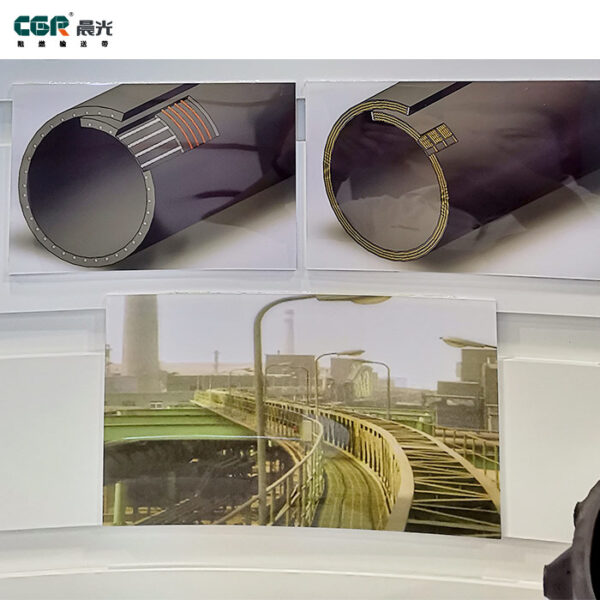

Las cintas transportadoras tubulares generalmente se dividen en dos tipos: cintas transportadoras tubulares con núcleo de tela y cintas transportadoras tubulares con núcleo de cable de acero según los diferentes materiales del esqueleto de carga utilizados.

Características estructurales

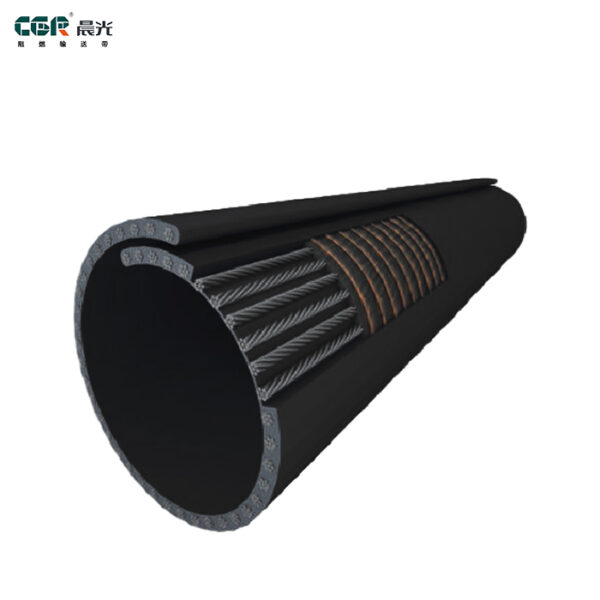

La estructura de la banda transportadora tubular difiere de la de una banda transportadora convencional. Su función principal es garantizar la tubularidad necesaria. Según los diferentes requisitos de rigidez de la banda, la estructura se ajusta específicamente. La estructura de las bandas transportadoras tubulares en capas generalmente se compone de un núcleo de lona, una capa de recubrimiento de caucho, caucho en los bordes y adhesivo. También requiere una capa de transición, y algunas requieren una capa rígida transversal. La estructura de las bandas transportadoras tubulares de cable de acero generalmente se compone de un núcleo de lona, una capa de recubrimiento de caucho, caucho en el núcleo de caucho, una capa de transición, una capa rígida transversal, etc.

Dependiendo del diámetro de la tubería y la naturaleza del material transportado, las bandas transportadoras tubulares con núcleo de tela suelen ser de dos tipos: estructura ordinaria y estructura de capa de transición. A diferencia de las bandas en capas, las bandas transportadoras tubulares con núcleo de cable de acero no tienen fibras de esqueleto conectadas horizontalmente. Su resistencia transversal se debe principalmente a la resistencia del propio caucho, y su fuerza de soporte es relativamente insuficiente. Para garantizar la tubularidad necesaria, se suele añadir una capa rígida transversal entre el caucho de recubrimiento y el cable longitudinal.

Para evitar la aparición de fenómenos como tuberías colapsadas, tuberías torcidas, tuberías planas, etc. que no se pueden utilizar normalmente, se debe lograr un valor de rigidez transversal razonable de la cinta transportadora, y el valor de rigidez lo proporciona principalmente el sistema de transporte y lo realiza la estructura de la cinta.