Learn more about Chenguang

Steel And Metallurgy

Innovative technology · excellent quality · global service

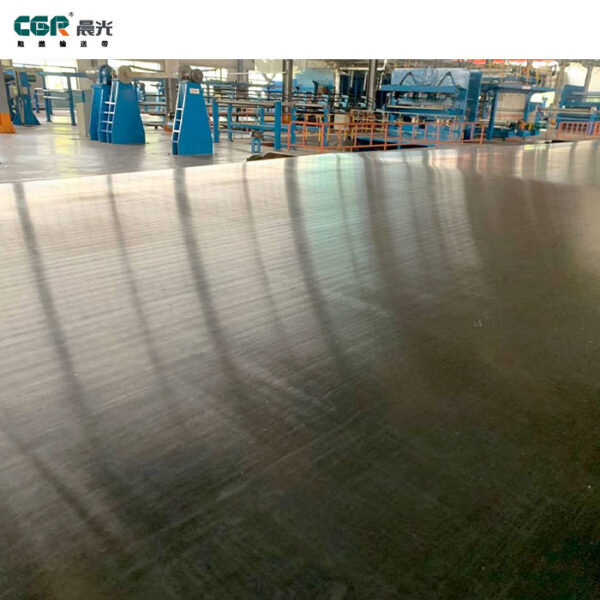

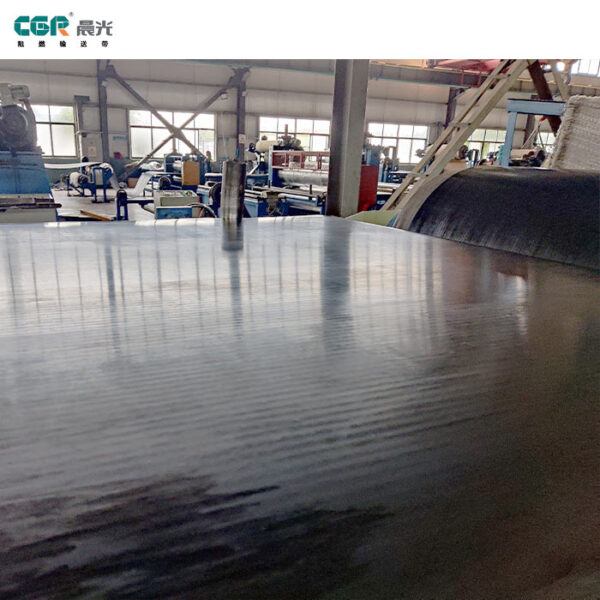

Iron and steel metallurgy high temperature heavy load

Solutions for the Steel and Metallurgical Industries

The harsh environment of iron and steel metallurgy places extremely high demands on the performance of adhesive tapes. In response to this demand, Chenguang Adhesive Tape has developed special solutions that are resistant to high temperatures and impacts, which are suitable for multiple production lines in iron and steel metallurgy to ensure efficient production and help reduce costs and improve efficiency.

Exclusive solution for Chenguang Conveyor Belt

Chenguang tape high temperature and heavy load solution

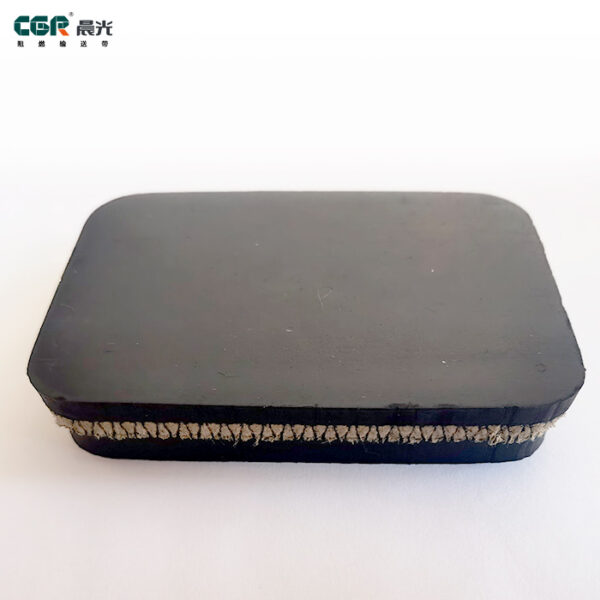

Steel metallurgy is subject to high temperature, heavy load, and multiple pollutants, so conveyor belts need to be highly resistant. Chenguang flame-retardant steel wire conveyor belts and aramid fabric core flame-retardant conveyor belts solve the problem. Steel wire belts are impact-resistant and suitable for high-temperature material transportation; aramid belts are high-temperature resistant and have high modulus, meeting the transportation needs of metallurgical production lines (such as continuous casting and hot rolling) and ensuring efficient processes.

Global Market Expansion – FAQs

Answers on Exporting Chinese Quality Worldwide

How can the tape ensure stability in extreme working conditions such as high temperature/low temperature?

Relying on advanced equipment and self-developed formula, tested by the National Rubber Products Quality Inspection Center, the wear resistance exceeds the industry standard by 35%, and the lifespan in mining scenarios is extended by 6 months.

How can the tape ensure stability in extreme working conditions such as high temperature/low temperature?

Is the flame retardant effect of flame retardant conveyor belts long-lasting? Will the performance decrease over time?

In response to environmental protection policies, what green technology applications are there in tape production?

Is the R&D cost of customized tape high? Is small batch customization feasible?

In response to environmental protection policies, what green technology applications are there in tape production?

How long is the delivery cycle for domestic regular orders and urgent orders? How long does it take for overseas orders including sea transportation?

Domestic: 15-25 days for normal orders, 7 days for urgent orders (≤1000 meters);

Overseas: 45-60 days including sea transportation, in cooperation with Sinotrans, the fastest arrival time for Russian projects is 35 days.

Overseas: 45-60 days including sea transportation, in cooperation with Sinotrans, the fastest arrival time for Russian projects is 35 days.

When purchasing tapes for different industries (mining/logistics/metallurgy), is there a dedicated service team to provide solutions?

What steps are involved in the process of purchasing tape? Can the contract be signed online and what is the corresponding payment method?

When cooperating on overseas projects, how do you deal with cross-border communication and cultural differences?

What exclusive rights, application conditions and quotas do strategic customers have?

Are there any price discounts for bulk purchases of tapes? What does the after-sales service include and how long will it take to respond?