1. Product Classification

This product has a wide variety and is widely used. According to different safety performance requirements, it is often divided into three categories: one is “general purpose fabric core conveyor belt” (hereinafter referred to as ordinary belt); the second is “general purpose fabric core flame retardant conveyor belt” (hereinafter referred to as flame retardant belt), and the third is “fabric laminated flame retardant conveyor belt” (hereinafter referred to as flame retardant belt). Flame retardant and flame retardant belts are ordinary belts with different safety performance requirements. At the same time, according to the different skeleton materials used, they can be divided into cotton canvas layered conveyor belts (CC), polyester layered conveyor belts (EP), nylon layered conveyor belts (NN), etc.; according to different use environments, they can be divided into oil-resistant layered conveyor belts, cold-resistant layered conveyor belts, heat-resistant layered conveyor belts, acid-resistant and alkali-resistant layered conveyor belts, etc.

2. Main Uses And Scope Of Application

The layered fabric core conveyor belt has a light body, high modulus, impact resistance, and good elasticity. It is widely used in coal, ports, metallurgy, chemical industry, building materials, electricity and other fields. It is suitable for conveying materials in medium and short distances and medium transportation occasions. Ordinary belts are mainly used to transport materials in general situations; flame-retardant belts are usually used to transport materials such as coal that have flame-retardant requirements outside of mines, and have certain flame-retardant and antistatic properties; flame-retardant belts are used to transport flammable materials such as coal in coal mines, and have good flame-retardant and antistatic properties.

3. Product Implementation Standards

The structure, performance and size series of this product comply with the following standards, and products can also be designed and manufactured according to customer needs and relevant requirements.

(1) Ordinary belts comply with the National Standard of the People’s Republic of China GB/T 7984-2013 “Ordinary Purpose Fabric Core Conveyor Belt”;

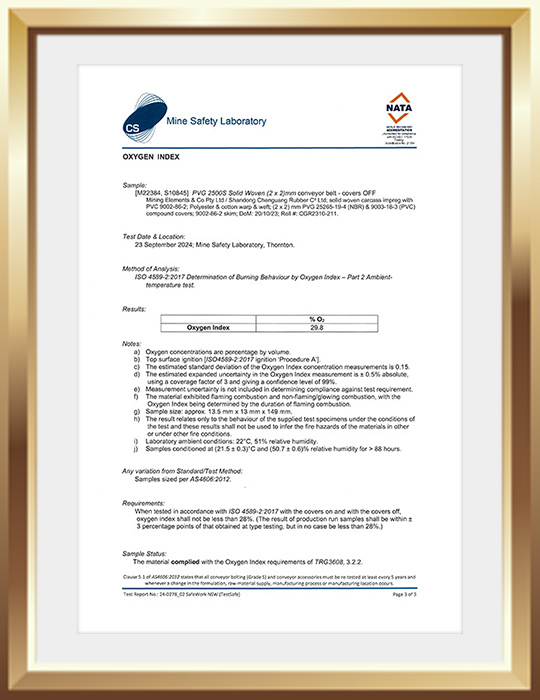

(2) Flame-retardant belts comply with the National Standard of the People’s Republic of China GB/T 10822-2014 “General Purpose Fabric Core Flame-retardant Conveyor Belt”;

(3) Flame-retardant belts comply with the Coal Industry Standard of the People’s Republic of China MT/T 914-2019 “Fabric Core Flame-retardant Conveyor Belt for Coal Mines”.

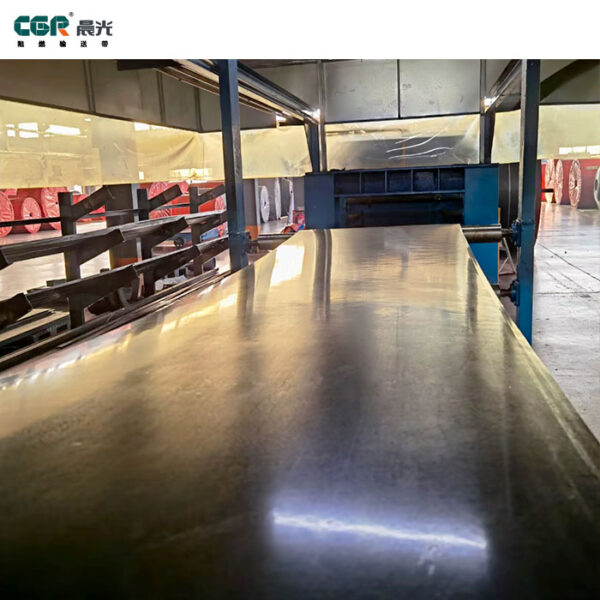

Structural Features

This product is usually composed of four parts: multiple fiber fabric layers, upper and lower cover glue, adhesive and edge glue. The middle skeleton force-bearing body is a multi-layer natural fiber or chemical synthetic fiber canvas, which is covered with covering rubber with required performance on the upper and lower sides. The middle glue is vulcanized to bond the multi-layer fiber canvas and the upper and lower covering rubber together.