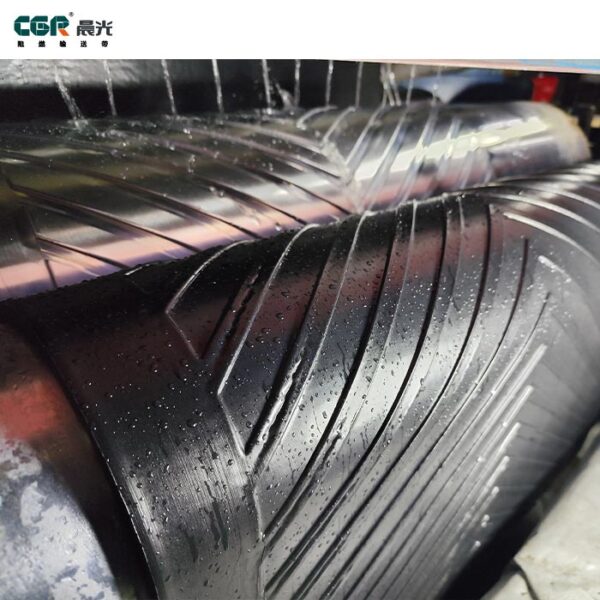

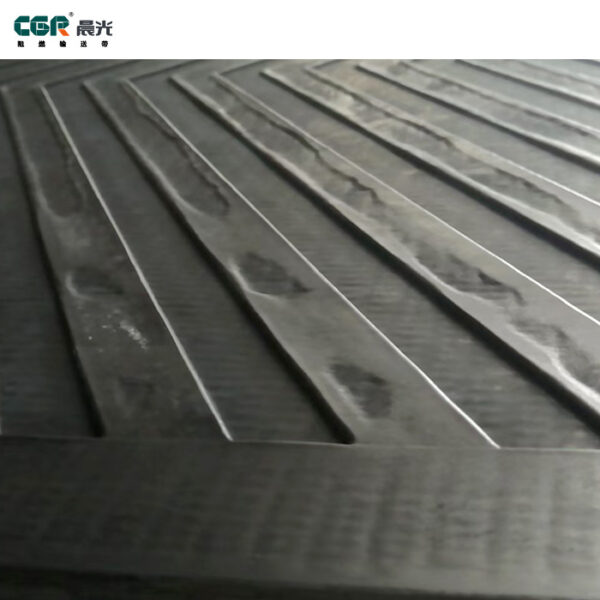

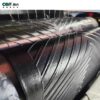

Patterned conveyor belts, also known as patterned belts, are a special type of conveyor belt that has different patterns on the surface to increase friction and prevent materials from sliding or rolling during transportation. Patterned conveyor belts are mainly used for inclined conveying and transporting materials that require additional friction, such as granular, powdery or blocky materials.

The Following Are Some Common Features And Advantages Of Patterned Conveyor Belts:

1. Good anti-slip performance: The pattern can increase surface friction, prevent materials from sliding, and ensure stable transportation.

2. High wear resistance: Patterned conveyor belts are usually made of wear-resistant rubber and can be used for a long time under heavy loads and harsh conditions.

3. Suitable for inclined conveying: The pattern can provide better traction, making the conveyor belt suitable for inclined conveying, such as ascending or descending conveying.

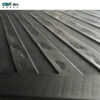

4. Diverse pattern selection: Patterned conveyor belts have a variety of patterns to choose from, such as V-shaped, U-shaped, lateral convex, etc. According to different materials and usage requirements, you can choose the appropriate pattern.

Patterned conveyor belts are widely used in material transportation in mining, ports, building materials, grain processing, chemical and other industries. When selecting a patterned conveyor belt, it is necessary to determine the appropriate pattern type and specifications based on the specific material properties, working environment and conveying requirements.