1. Product Classification And Characteristics

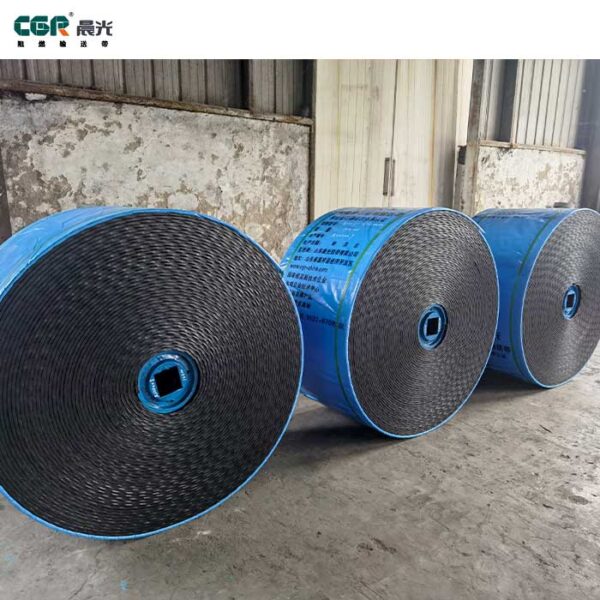

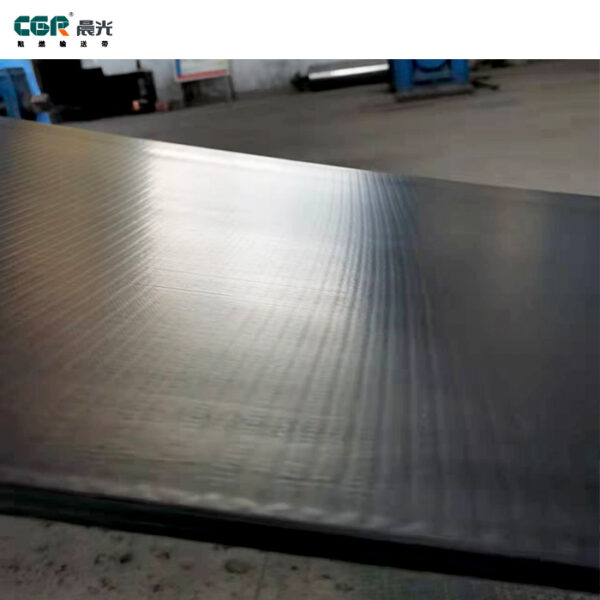

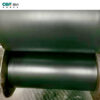

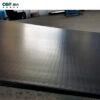

This product can be divided into two categories according to the properties of the covering layer material: one is “plastic surface whole core flame retardant conveyor belt” (hereinafter referred to as PVC conveyor belt); the other is “rubber surface whole core flame retardant conveyor belt” (hereinafter referred to as PVG conveyor belt).

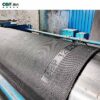

The belt core is woven into a three- to five-layer overall structure using polyester industrial filament, nylon yarn and cotton thread. It has the characteristics of high strength, large transportation volume and stable transportation; at the same time, the product has excellent flame retardant, anti-static, impact resistance, wear resistance and corrosion resistance.

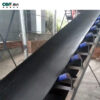

2. Main Uses And Scope Of Application

This product is mainly suitable for coal transportation in coal mines, and can also be used for mechanical transportation in metallurgy, ports, cement and chemical industries. PVC conveyor belts are suitable for transporting materials under dry conditions with an inclination of less than 16°, and PVG conveyor belts can be used for dry or wet conveying occasions with an inclination of less than 20°. It has better climbing ability, larger transportation volume, and better wear resistance.

3. Product Implementation Standards

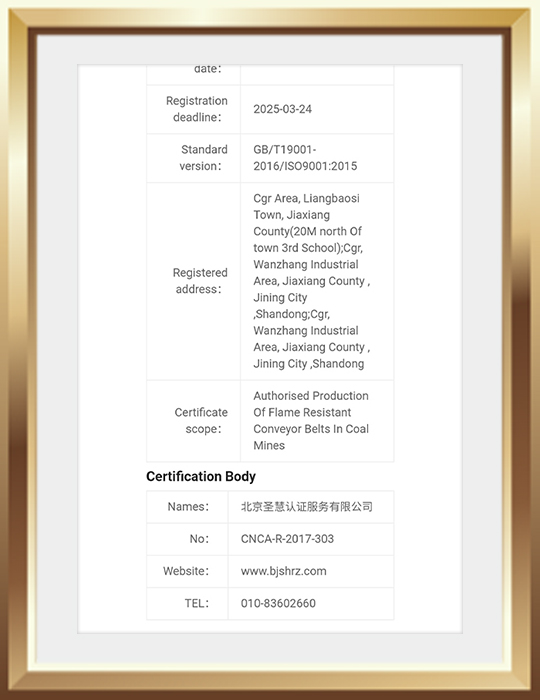

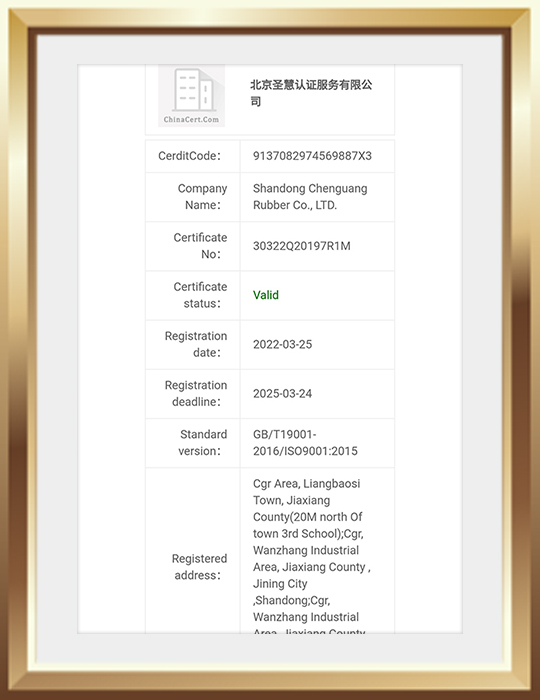

This product complies with the MT/T 914-2019 “Textile Core Flame Retardant Conveyor Belt for Coal Mines” standard of the coal industry of the People’s Republic of China, and can also be based on customer requirements.

Structural Features

This conveyor belt consists of three parts: an integral belt core, polyvinyl chloride impregnation paste, and a covering layer. The integral belt core is the skeleton material of the conveyor belt. The polyvinyl chloride plasticized paste is used to fill the impregnated belt core. The polyvinyl chloride plasticized paste is formed by a combination of chemical raw materials with various properties to ensure the safety performance required by the conveyor belt, such as flame retardancy and antistatic properties. The covering layer determines the transportation characteristics, impact resistance, wear resistance, and corrosion resistance of the conveyor belt. It is formed by high-temperature plasticization or flat vulcanization.